Industry

view moreJiahao Xinda Technology

Founded In 2009, The Shenzhen-Based Jiahao Xinda Technology Co., Ltd. Is A Pure-Play Enterprise Dedicated To Developing And Manufacturing Nonstandard Machine Parts And Equipment Processing, Covering An Area Of 12600 Square Meters. Our Plants Are Located In Fuyong Town, Baoan District, Shenzhen City, Boarding Hongkong On The South And Macao On The West And Enjoying Convenient Transportation.We Also Have Branch Of Dongguan And Nantong Plants For Production.

JHXD Headquarter Located In Shenzhen And Have Branches In HK, Jiangsu,Dongguan .We Total Have Three Manufacture Plants For Production .

Owning Advanced Technologies And Strong Technical Force, We Are Employing Over 100 Staffs And 20 Of Whom Are Supervisory Engineering Staff...

about us

JHXD Headquarter Located In Shenzhen And Have Branches In HK, Jiangsu,Dongguan .We Total Have Three Manufacture Plants For Production .

Owning Advanced Technologies And Strong Technical Force, We Are Employing Over 100 Staffs And 20 Of Whom Are Supervisory Engineering Staff...

Our Advantages

Normally, We Can Produce The Samples Parts In 5-7 Days And 15-20 Days For The Mass Production . When Parts Done , We Have Our Forwarder To Ship The Parts Out With Delivery Of 3-5 Days To Your Door . Fast Delivery Will Help You To Achieve Your Busines.

We Have Strict QC Check Standard For All The Parts. All Check The Samples And Sampling For The Mass Production.

ISO 9001-2008 Quality Certification System Help Us To Avoid The Quality Problem.

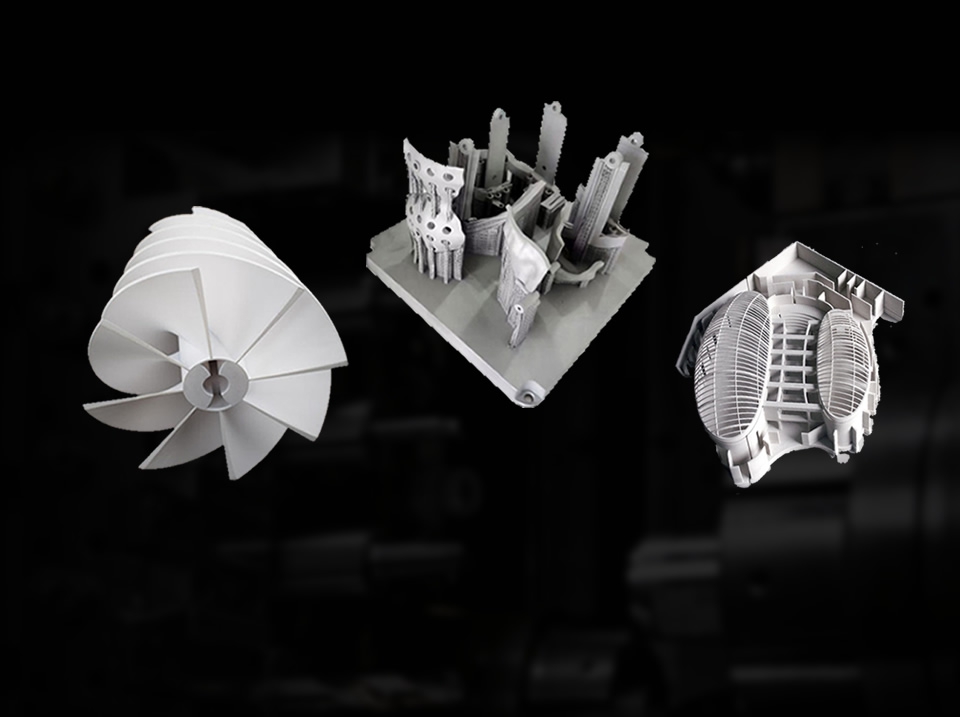

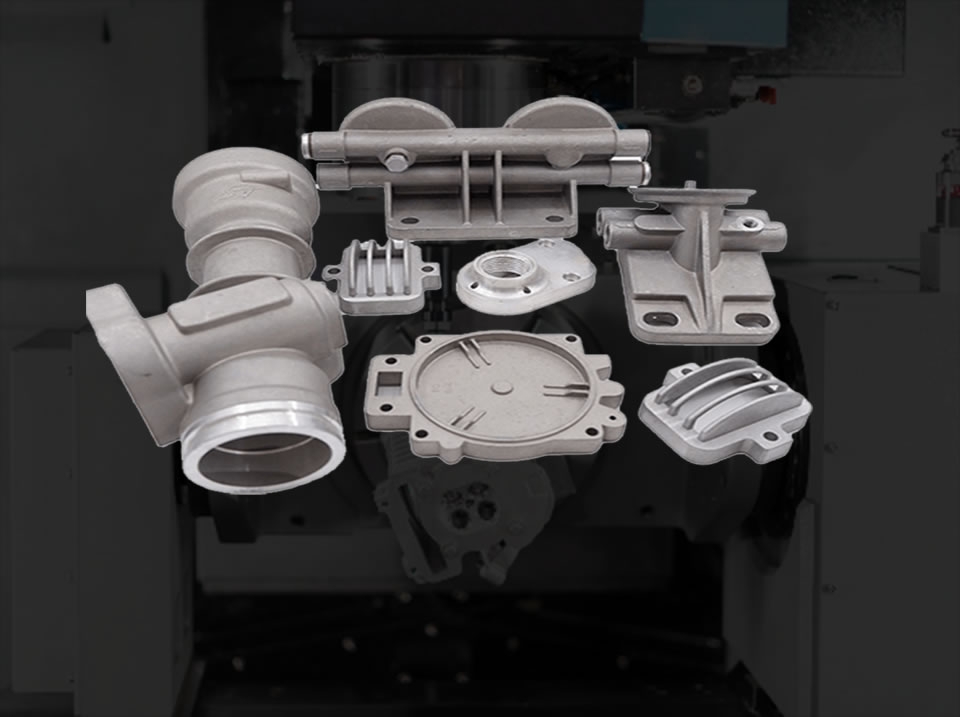

We Have Over 100 Professional Manufacturing And Possessing Equipment, Which Includes CNC, Milling Machine, Lathe, Precision Grinder And Wire Cutting Machine, 28 Precision Punching Machines With Different Tonnages From 20 To 300 Ton;With 15 Sets Cold-Chamber Die Casting Machine From 250-800 Ton.

We Have Whole Team For The Machining Process . Including The Production Team / QC Team/ Finance Team / Administration Team/Management Team/ Oversea Market Team /Outsource Team / Purchasing Team Etc. [Read More]

We Have Strict QC Check Standard For All The Parts. All Check The Samples And Sampling For The Mass Production.

ISO 9001-2008 Quality Certification System Help Us To Avoid The Quality Problem.

We Have Over 100 Professional Manufacturing And Possessing Equipment, Which Includes CNC, Milling Machine, Lathe, Precision Grinder And Wire Cutting Machine, 28 Precision Punching Machines With Different Tonnages From 20 To 300 Ton;With 15 Sets Cold-Chamber Die Casting Machine From 250-800 Ton.

We Have Whole Team For The Machining Process . Including The Production Team / QC Team/ Finance Team / Administration Team/Management Team/ Oversea Market Team /Outsource Team / Purchasing Team Etc. [Read More]